Building Systems & Data

Course Instructor: Prof. Russell Gentry

Single Member: Kiran Golla

Building Systems and Data focuses on the overlap between AEC (Architecture, Engineering, Construction) processes and the building models and data that support them.

The aim is to develop building models, workflows, and specify exchanges that describe the generation, hosting, manipulation, and transfer of this information through its life cycle. Through database tools, scripting, plug-ins, and API programming students will implement their workflow in BIM and database systems.

In the process of developing the capabilities in database design and implementation, scripting, API programming, etc., a use-case in the industry is considered and developed further in terms of optimizing data managing methods.

Wall Framing Automation - Metal Stud Wall Construction

Offsite Fabrication

Off-site construction involves the process of planning, designing, fabricating, transporting and assembling building elements for rapid site assembly to a greater degree of finish than in traditional piecemeal on-site construction.

It can service a variety of building and construction typologies including education, housing, health care, office, government, dormitory, retail, and hospitality.

Pre-Panelization

Factoring the limitations of the offsite fabrication of metal framing, its transportation, assembly systems, and modularity, the wall(s) may be separated into segments.

These segmented modules are then considered to form a framing panel and subsequently fabricated offsite.

Depending on the nature of the project this process of panelization could be optimized to generate a minimum number of unique modules.

Automation & Scope

This automation will facilitate the prefabrication of non-load-bearing steel stud walls created directly from the BIM model.

The scope is narrowed down to Interior non-structural metal stud wall systems.

Stakeholders

Designer

Creates an interior partition (wall) layout.

Assigns wall types and data to generate a BIM Model.

Optimizes the wall panel units as per the design and generates the framing model with associated data accordingly.

Contractor

Responsible for inspecting and generating the material quantities.

Order Material.

Construction Schedule.

Coordinates the fabrication and assembly process.

Manufacturer

Provides the Materials availability, purchase options, and specifications.

Takes the order and ships material.

Fabricator

Design assistance.

Shop drawings.

Production of wall panels(as per the drawings) at the factory and the delivery and assembly on site.

Process

The interior wall layout is analyzed,

Segments are identified based on the corner, door & opening conditions, production & shipping limitations,

The paneled wall pieces are highlighted to check the results,

The stud members are propagated across the selection of walls and are groups accordingly.

Business Process Model & Notation (BPMN)

Key Exchanges

Designer >>

Fabricator >> Designer

Manufacturer >> Designer

Manufacturer >> Designer

Designer >>

Designer >>

: Creates BIM Model with wall information

: Provides design assistance, like panelization rules, etc.,

: Provides product-related information and Specification

: Provides product’s geometry/model data

: Prepares BIM model containing Pre-panelized Metal Framing information

: BIM Model is used to produces Construction Documents and Schedules

Key Exchanges

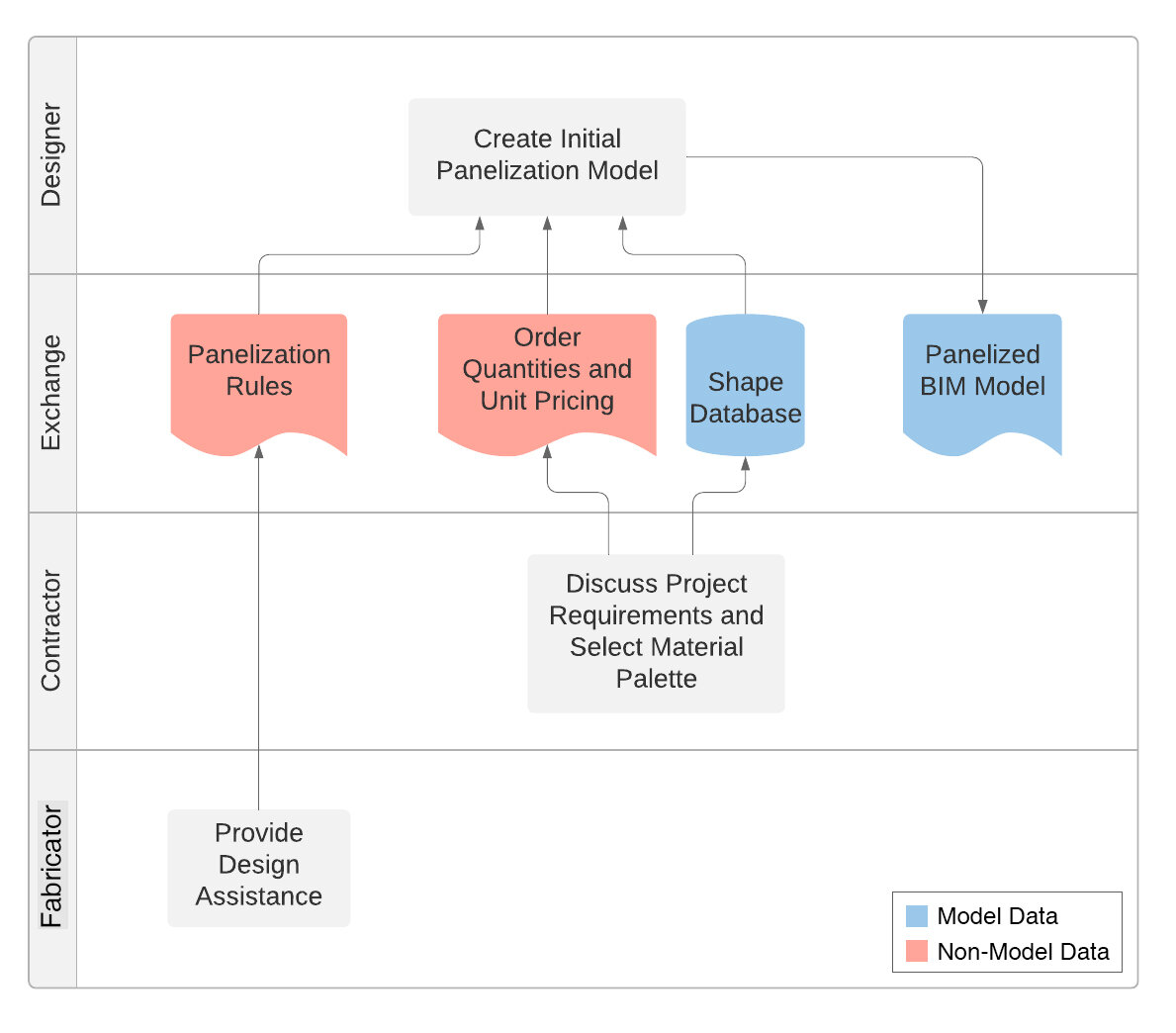

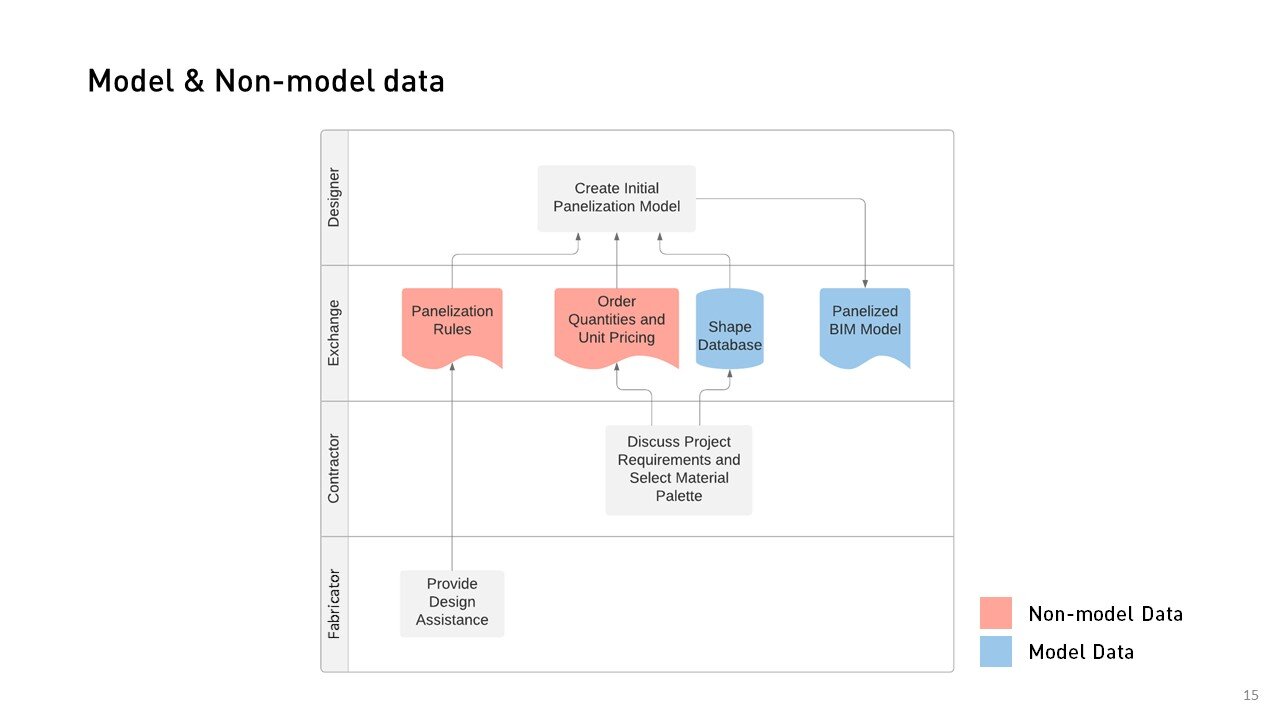

Model Data & Non-Model Data

Data Schema (Overview)

UML Class Diagram

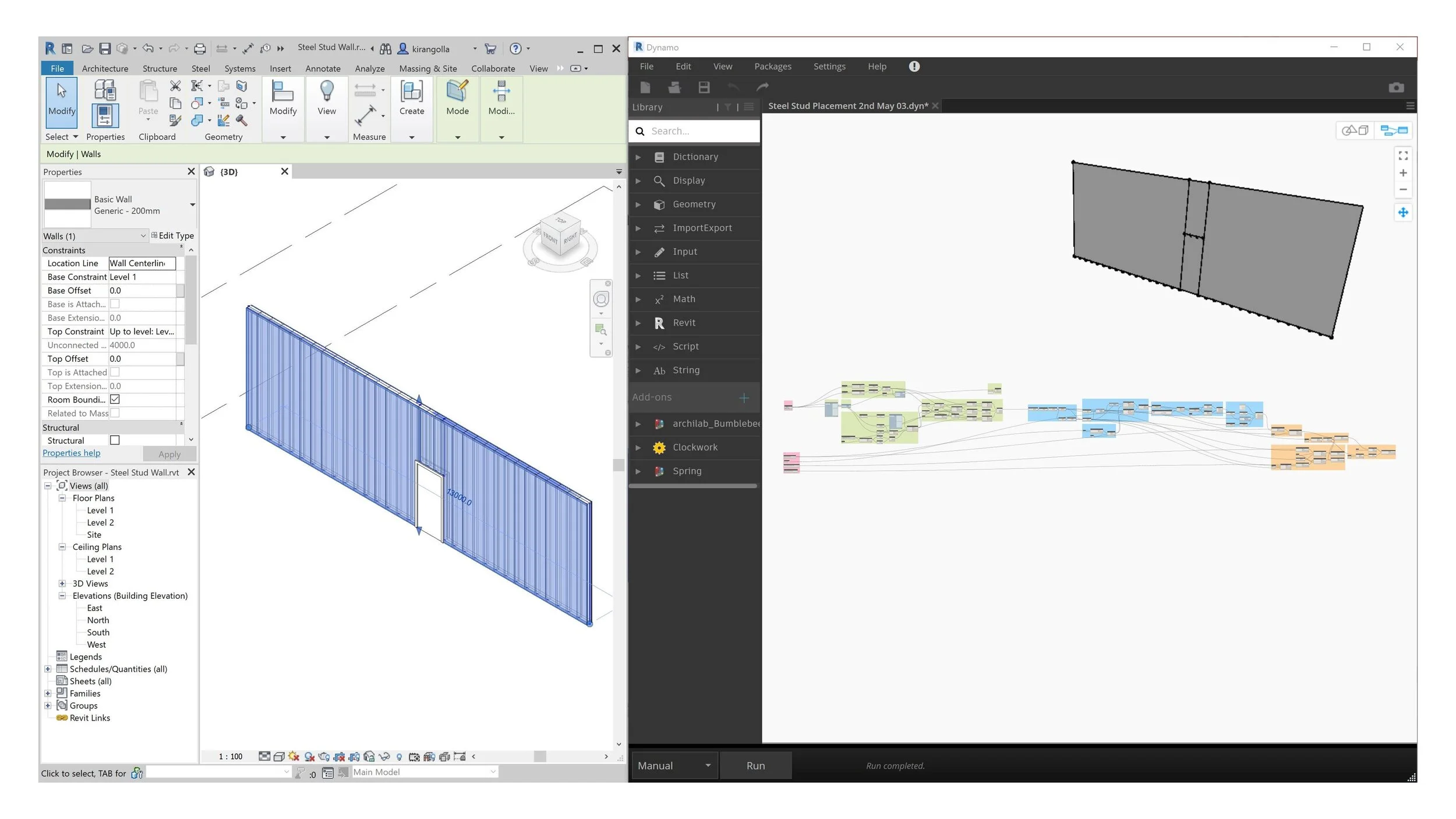

Automation process - Illustrated

Case 01 – Only Wall Condition

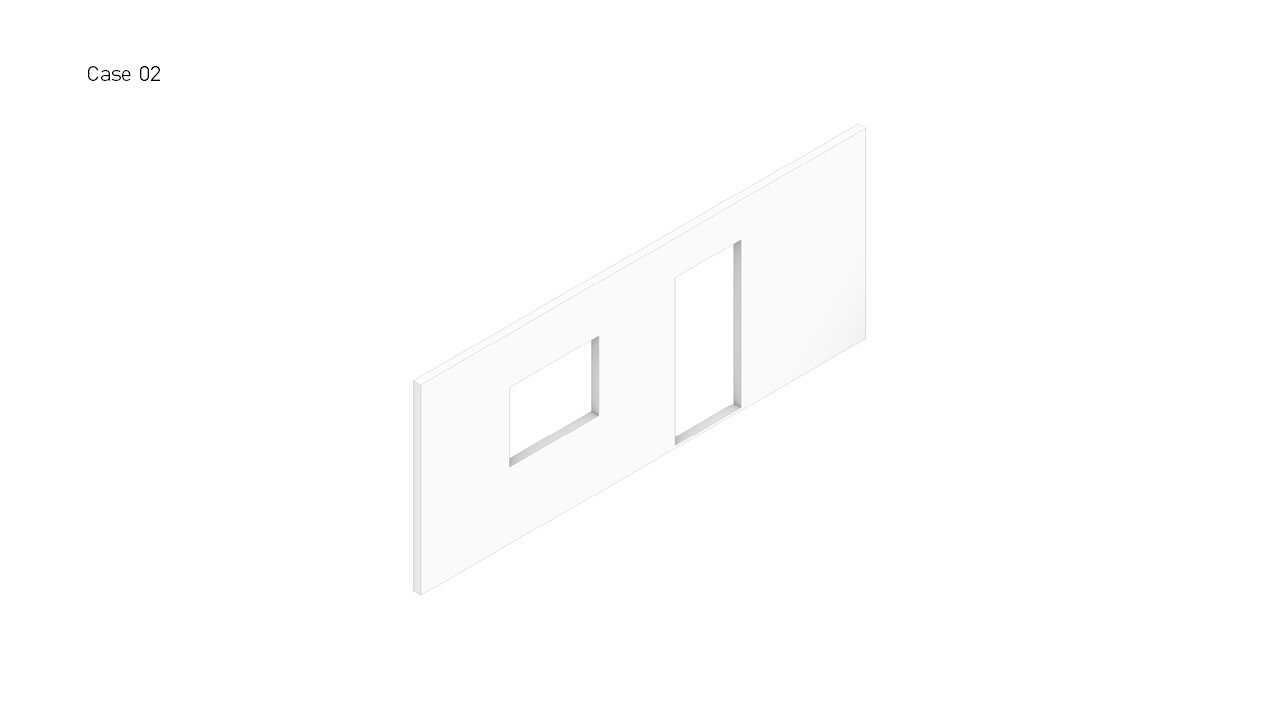

Case 02 – Wall with Window & Door Opening

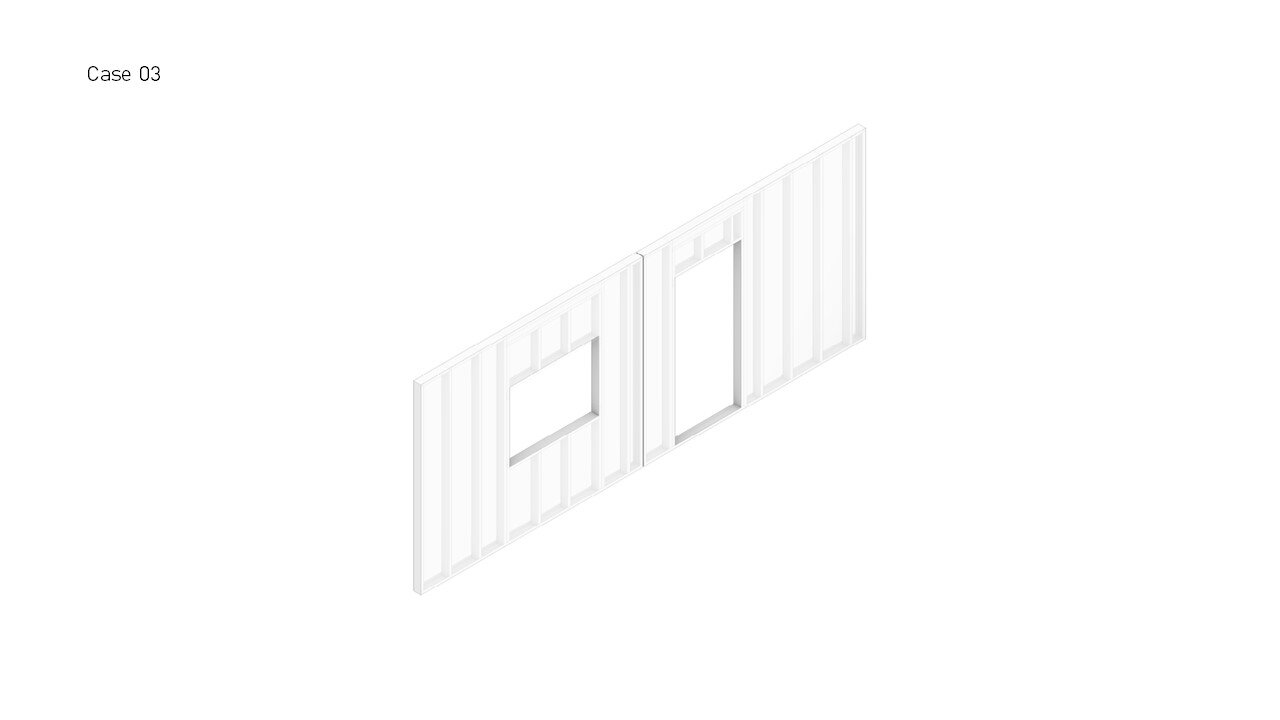

Case 03 – Segmentation of the Wall with its hosted components

Revit-Dynamo execution

Screenshot of the Automation process